The Power of Cloning RO Membrane Performance

It has become a standard industrial practice in medium and large-scale water treatment systems to operate multiple skids of reverse osmosis (RO) membranes. However, a persistent challenge confronts system operators — the potential for fouling or scaling issues.

Interrupting the entire operation to address RO membrane performance issues becomes more than an inconvenience; it’s a substantial setback. In these large-scale setups, every pause in operation results in the loss of time, money, and productivity.

The questions that arise are straightforward:

- Can we identify and address RO system issues without needing to take the system offline for troubleshooting?

- Is there a practical solution for troubleshooting and optimizing membrane performance without sacrificing the continuous flow of water and wastewater treatment processes?

The Avista™ Black Box provides a pragmatic answer to this question.

In the next sections, we scrutinize the challenges of using membrane technologies and maintaining uninterrupted operations in the face of membrane fouling and scaling. We examine how the Avista™ Black Box is a powerful tool for cloning membrane performance tailored to the needs of chemical engineers and technicians in the field.

Avista Black Box in Action

The Avista™ Black Box is a proprietary, stand-alone, non-intrusive monitoring device that replicates performance for spiral wound RO membranes.

The Avista™ Black Box can evaluate both pilot and full-scale spiral wound RO membrane systems.

Avista Black Box: Key Features & Advantages

Avista experts conduct an in-depth analysis over several months, allowing them to thoroughly study the foulant and optimize the cleaning frequency. This proactive approach ensures the most effective cleaning process for membrane systems, preventing unnecessary disruptions and reducing costs.

Below are several more benefits of using the Avista™ Black Box to clone membrane performance.

1. Collect Data Without Interfering with System Operation

The device provides real-time data analytics, offering actionable insights for proactive decision-making and optimization of RO membranes over time.

Through membrane performance replication, Black Box allows you to collect data on system trends over time to generate real results without sacrificing a membrane for an autopsy.

2. Connects to Various Locations

The Avista™ Black Box can be connected to various locations within the membrane system. Three connection options exist: the feed inlet, the inter-stage, and the concentrate/permeate.

The Avista™ Black Box can capture issues in feedwater variability that can’t be detected in intermittent data points. It can analyze potential fouling, evaluate anti-scalant performance, and detect difficult-to-identify problems in the feed or concentrate.

3. Self-Contained Monitoring Device

The Avista™ Black Box eliminates the need for complex installations or integration with existing systems. It allows continuous, non-intrusive monitoring without disrupting the operation of reverse osmosis systems. It’s also designed to be maintenance-free, which is ideal for pilot testing and full-scale evaluation.

Case In Point: Unexplained Membrane Fouling

To demonstrate the key features of Avista™ Black Box, here’s a case that underscores the Black Box’s pivotal role in diagnosing and rectifying membrane issues, ensuring sustained efficiency and reduced operational disruptions.

Here’s the overview of the case study.

The Problem

In a real-world scenario, an industrial membrane system operating 24/7 experienced fouling issues, causing a decline in membrane performance.

While cleaning was conducted every 30 days, the root cause of the problem remains unidentified.

The Solution

An Avista™ Black Box monitoring device was installed at the first stage of the system to model foulant deposition.

While the system continued to run, an autopsy was performed on the Black Box. The autopsy results identified colloidal fouling and the presence of organics on the membrane surface. Then, a cleaning study was conducted on the Black Box membrane to identify cleaning chemicals capable of restoring proper membrane flow and pressure.

The Outcome

Once the multimedia filter was repaired and the membranes properly cleaned, the system was back online.

The customer now reports better permeate water quality and higher water production. The operating pressures have been reduced, the system is cleaned every six months, and proper performance levels are restored after each cleaning.

In the following sections, let’s see how exactly Avista™ Black Box plays a pivotal role in diagnosing the issue.

How To Use The Avista Black Box For Membrane Fouling & Scaling Detection

The Avista™ Black Box can detect membrane performance issues for diagnosis without compromising full-scale operations. Here’s how.

First, you connect the unit to the membrane system. In this case, the Black Box was connected to the first stage or the feed location.

Then, the unit collects key parameters for proper data monitoring. Lastly, corrective actions will be determined by the Avista™ team after gathering expert insights from data interpretation and autopsy analysis.

Here’s the step-by-step process:

Connect to Various Locations in the RO Membrane System

The Avista™ Black Box is a portable, self-contained apparatus that can simulate the membrane performance closest to the sampling location. It has feed, permeate, and concentrate streams that can easily be installed in pilot or full-scale RO systems.

You can connect the Avista™ Black Box in three locations:

FEED

Connecting the unit to the feed inlet of the RO membrane filtration system can:

- Analyze the potential for colloids, organic matter, and biological fouling in the incoming feed water. This is possible when the pretreatment system is not effectively filtering suspended solids.

- Determine the effects of oxidizers on lead membranes.

- Provides early warning signs for potential issues in the initial stage of the RO process.

SECOND STAGE (INTER-STAGE)

Connecting to the second stage can:

- Detect problems that are challenging to identify in the feed or concentrate, offering a more detailed analysis.

- Locate unique inter-stage foulant deposits.

- Confirm the proper functioning of the pretreatment system between stages.

CONCENTRATE

Connecting to the downstream system in the concentrate line can:

- Identify potential scale formers in the concentrate, helping to prevent scaling issues in the system.

- Evaluate the performance of antiscalant chemicals.

- Test and optimize recovery rates by monitoring the concentrate stream.

Installation takes mere minutes, and additional units can be added for the simultaneous achievement of multiple monitoring goals.

Data Monitoring & Interpretation

Once installed to the RO system, the Avista™ Black Box can monitor and track many parameters, such as flow rate, pressure, conductivity, and temperature readings.

These data are pre-tested to establish a performance baseline. The Avista™ tech team performs data normalization. After the onsite study, the unit is also tested to evaluate post-test performance.

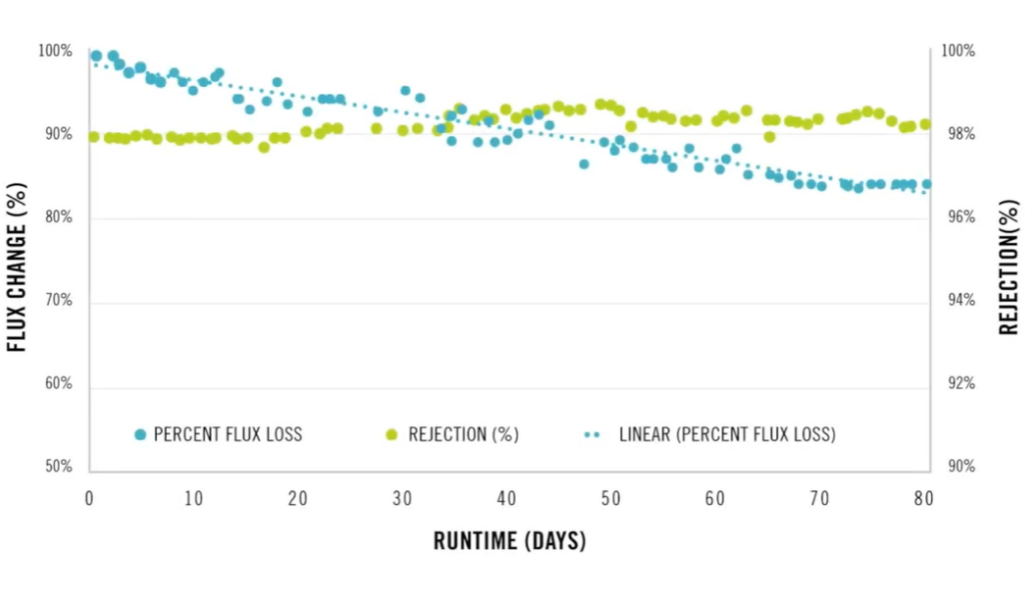

After data collection and normalization, a graph will be provided by the Avista™ team, comprised of skilled water engineers and technicians, to determine areas for improvement.

After the onsite test, the Avista™ Black Box is returned for autopsy to diagnose membrane fouling and determine cleaning chemicals and recommendations. Avista™ will recommend the appropriate cleaning chemicals specific to your RO system depending on the autopsy results.

Multimedia Filter Repair & Membrane Cleaning

Implementing the Avista™ Black Box at the system’s first stage allowed for pinpointing the malfunction of a multimedia filter at the pretreatment stage, a crucial finding that may have otherwise gone unnoticed.

When removed after an 8% flux decline, an autopsy revealed colloidal fouling and the presence of organic matter. Further investigation identified a malfunctioning multimedia filter at the pretreatment stage.

Guided by the comprehensive analysis provided by the Black Box, a follow-up cleaning study was carried out. This study not only restored the membrane’s optimal flow rate and pressure but also led to a series of advantages for the industrial membrane system, including:

Improved Water Quality

The customer reported better permeate water quality, reflecting the effectiveness of the Black Box as an instrument for identifying and addressing fouling issues.

Increased Water Production:

The system achieved higher water production with optimized pre-treatment conditions, enhancing overall operational efficiency.

Reduced Operating Pressures:

A cleaning study was conducted on the Black Box membrane to identify cleaning chemicals that restore proper membrane flow and pressure. Operating pressures were significantly reduced, indicating a more streamlined and efficient water treatment process.

Extended Cleaning Cycles:

The system’s chemical cleaning frequency was extended from every 30 days to every six months, showcasing the long-term impact of the Avista™ Black Box in using less chemicals and minimizing downtime.

Restored Performance Levels:

According to normalized data, proper performance levels were consistently restored after each cleaning. This demonstrates the sustained benefits of proactive monitoring and optimization.

By providing real-time insights and facilitating detailed analysis without interrupting operations, the Black Box becomes instrumental in addressing underlying issues, enhancing system efficiency, and delivering tangible, long-term benefits to the end-users.

Unlock Peak Reverse Osmosis Performance with Avista Black Box Services

The power of cloning membrane performance with the Avista™ Black Box extends beyond diagnosis–it transforms how you manage, optimize, and preserve your RO membranes.

With Avista lab services such as CEI, Water Analysis, Cell Test Cleaning, and Filtration Study, you’ll experience enhanced efficiency, reduced operational disruptions, and extended membrane life.

Contact our Membrane System Experts Today to Harness the Full Potential of your Operations.