RO System Optimization

Finding a Stable Cleaning Regime

BACKGROUND

A consulting engineering firm selected to design and oversee the construction of a 5-mgd reverse osmosis (RO) system for a Southern California military facility handed over the system to an operations management firm. Upon handover, the OEM of the system recommended that the management firm contact Avista™ Technologies for support with analytical membrane services, antiscalant recommendations, and on-site technical training for the operators. Avista received the call and was onsite the same day to evaluate the system.

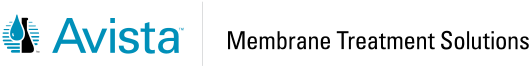

Once on-site, an Avista applications expert provided a technical audit of the system, evaluating operating conditions including pressure, flows, and conductivities. The system’s standard operating procedures and historical operating data were reviewed as well as chemical membrane compatibility standards.

Download our full case study to find out how through an in-depth system audit and analytical evaluation, silica was discovered to be the limiting system recovery factor.