Avista™ | Water Analysis

A water analysis provides a technical reference point for assessing system performance, ensuring water quality, and identifying potential issues such as scaling and fouling.

An Avista water analysis provides solutions supported by data tested in our lab to ensure your membrane system is optimized. For continued assistance with the RO system, we’ve created Advisor™Ci Online Chemical Dosing Software to optimize dose and recovery rates, ensuring your membranes are maintained properly and efficiently.

How An Avista™ Water Analysis Works

Sample Collection

A representative water sample must be collected from the feedwater source entering the RO water treatment system. The process begins with testing the water quality parameters of the sample, which vary depending on the customer’s goals.

Analysis of Water Quality Parameters

A thorough water analysis through lab tests is critical in selecting targeted and properly dosed membrane treatment chemicals for Reverse Osmosis (RO), Microfiltration (MF), Ultrafiltration (UF), and Nanofiltration (NF) systems of any water quality.

Feedwater properties and chemistry must be measured in the laboratory to accurately project and determine the system’s scale and/or fouling potential. Regardless on the feed source, Avista applies a standard water analysis procedure for the main purpose of assessing the scaling potential.

Water Quality Parameters

Physical test parameters include color, odor, temperature, total hardness, turbidity, total dissolved solids, and conductivity.

Meanwhile, chemical parameters include pH, alkalinity, total dissolved solids, and other possible contaminants like:

- Metals – copper, iron, aluminum, lead, mercury, zinc, etc.

- Compounds – cyanide, nitrate, sulfate, silica, ammonia, pesticides, or other minerals

- Microbes – coliform bacteria, E.coli, iron bacteria, etc.

- Specific ions – chlorides, fluorides, sodium, hexavalent chromium, etc.

Our Water Analysis Requirements

The following table provides details of the minimum acceptable levels of measurement in the feedwater to ensure that a full assessment and analysis of the scaling potential can be made. If the requested measurement accuracy cannot be provided, the level of antiscalant dosage projected may be higher than required.

| Parameter | Symbol | Measurement | Minimum Required Accuracy | Comment |

|---|---|---|---|---|

| Aluminum | Al | µg/litre | ±0.05 | |

| Calcium | Ca | mg/litre | ±3 | |

| Fluoride | F | mg/litre | ±0.1 | |

| Magnesium | Mg | mg/litre | ±3 | |

| Phosphate | PO₄ | mg/litre | ±0.2 | |

| Silica | SiO₂ | mg/litre | ±1 | Total silica should be measured |

| Strontium | Sr | µg/litre | ±50 | |

| Barium | Ba | µg/litre | ±10 | |

| Chloride | Cl | mg/litre | ±5 | |

| Iron | Fe | µg/litre | ±50 | Total iron and dissolved iron is useful |

| Manganese | Mn | µg/litre | ±50 | |

| Potassium | K | mg/litre | ±5 | |

| Bicarbonate | HCO₃ | mg/litre | ±3 | |

| Sodium | Na | mg/litre | ±5 | |

| Sulphate | SO₄ | mg/litre | ±3 | |

| Nitrate | NO₃ | mg/litre | ±2 | |

| Conductivity | µS/cm | ±10 | Provided as a double check on analysis. TDS can be provided instead | |

| pH | mg/litre | ±0.1 | ||

| Temperature | °C | ±1 | Seasonal max/min |

Parameters may be provided as mg/L CaCO3 or other units if desired. Carbonate/bicarbonate may also be provided as M and P alkalinity instead. Depending on the source of the feedwater and the final use of the product water selected, other parameters may be requested – for example, heavy metals or high levels of boron.

Uses & Benefits of Water Analysis

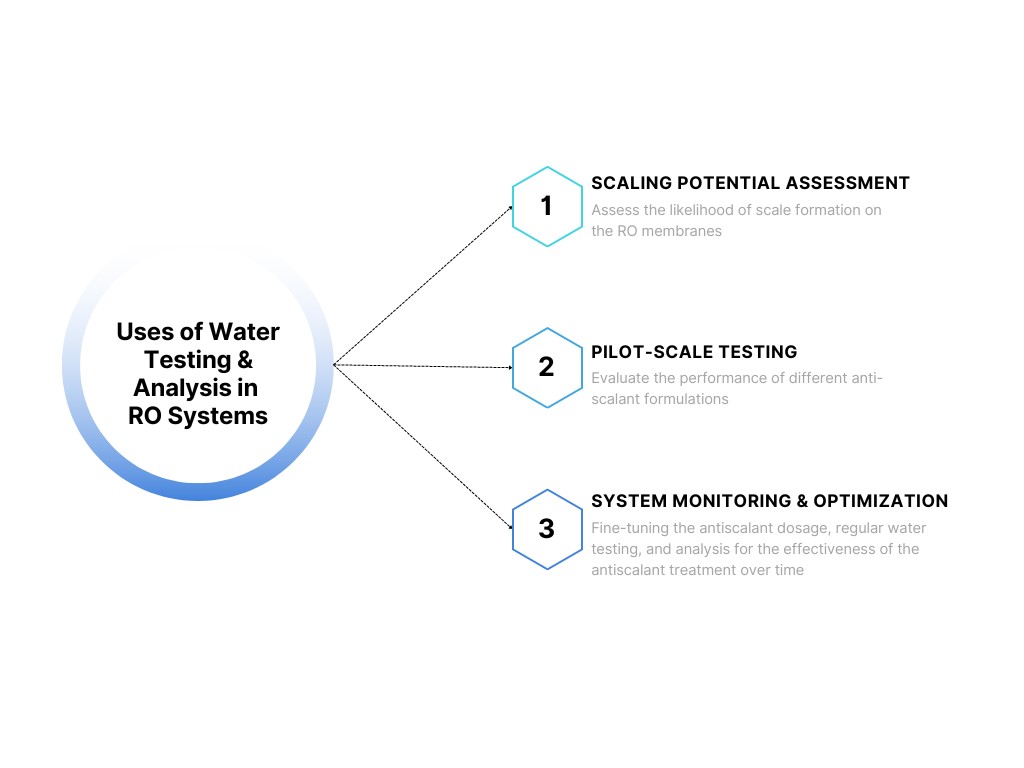

After water analysis, you can now optimize your membrane systems by:

Assessing the Scaling Potential

Assessing the Scaling Potential

Our Avista AdvisorCi™ projection software will use the water analysis results to determine recovery rates, antiscalant selection, dose rates, potential scales, and/or foulants.

Pilot-Scale Testing

In some cases, this involves running samples of a smaller-scale RO system with the selected antiscalant to monitor its effectiveness in preventing scale formation.

RO System Monitoring & Optimization

If scaling issues persist, adjust the water pretreatment regimen and fine-tune the antiscalant dosage. Regular testing and water analysis will also identify any changes in water quality, scaling potential, or the performance of the antiscalant, enabling timely adjustments if required.

With this approach, potential scaling/fouling issues can be detected, maintenance costs can be minimized, and membrane life can be extended by multiple years. See how Avista takes a systematic approach to scaling/fouling problems by first conducting a water analysis in our case studies.

Main Benefits of Avista Water Analysis Services:

- Advanced laboratory facilities equipped with state-of-the-art instruments and qualified staff.

- Detailed analysis of scaling potential and customized treatment recommendations

- Accurate water analysis reports with quick turnaround times.

- Achieve long-term cost savings and extended lifespan of RO systems through our anti-scaling solutions.

Schedule A Service Request

With in-depth knowledge and expertise in water treatment, our water treatment managers and accomplished chemical engineers offer practical insights and customized solutions aligned with your specific requirements.

Contact our technical support team for optimal solutions and witness remarkable results in your water treatment processes.

Assessing the Scaling Potential

Assessing the Scaling Potential